7.9 Controlling

Adapted by Stephen Skripak with Ron Poff

Let’s pause for a minute and reflect on the leadership and management functions that we’ve discussed so far. As the leader of Notes-4-You, you began by setting a vision, and establishing the culture needed to achieve that vision. You used all of your skills to draw in other people to work towards that vision. Then you worked as a manager: you set objectives, or performance targets, which you needed to meet in order to achieve your mission. you organized your company by allocating the people and resources required to carry out your plans. Finally, you provided focus and direction to your employees and motivated them to achieve organizational objectives. Is your job finished? Can you take a well-earned vacation? Unfortunately, the answer is no: your work has just begun. Now that things are rolling along, you need to monitor your operations to see whether everything is going according to plan. If it’s not, you’ll need to take corrective action. This process of comparing actual to planned performance and taking necessary corrective action is called controlling.

A Five-Step Control Process

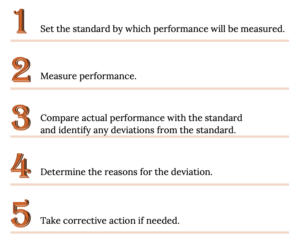

You can think of the control function as the five-step process outlined in Figure 7.7. Let’s see how this process might work at Notes-4-You. Let’s assume that, after evaluating class enrollments, you estimate that you can sell 100 notes packages per month to students taking a popular sophomore-level geology course. So you set your standard at 100 units. At the end of the month, however, you look over your records and find that you sold only 80. In talking with your salespeople, you learn why you came up 20 packages short: it turns out that the copy machine broke down so often that packages frequently weren’t ready on time. You immediately take corrective action by increasing maintenance on the copy machine.

Now, let’s try a slightly different scenario. Let’s say that you still have the same standard (100 packages) and that actual sales are still 80 packages. In investigating the reason for the shortfall, you find that you overestimated the number of students taking the geology course. Calculating a more accurate number of students, you see that your original standard—estimated sales—was too high by 20 packages. In this case, you should adjust your standards to reflect expected sales of 80 packages.

In both situations, your control process has been helpful. In the first instance, you were alerted to a problem that cut into your sales. Correcting this problem would undoubtedly increase sales and, therefore, profits. In the second case, you encountered a defect in your planning and learned a good managerial lesson: plan more carefully.

Benchmarking

could be considered as a specialized kind of control activity. Rather than controlling a particular aspect of performance (say, defects for a specific product), benchmarking aims to improve a firm’s overall performance. The process of benchmarking involves comparisons to other organizations’ practices and processes with the objective of learning and improvement in both efficiency and effectiveness. Benchmarking exercises can be conducted in a number of ways:

- Organizations often monitor publicly available information to keep tabs on the competition. Annual reports, news articles, and other sources are monitored closely in order to stay aware of the latest developments. In academia, universities often use published rankings tables to see how their programs compare on the basis of standardized test scores, salaries of graduates, and other important dimensions.

- Organizations may also work directly with companies in unrelated industries in order to compare those functions of the business which are similar. A manufacture of aircraft would not likely have a great deal in common with a company making engineered plastics, yet both have common functions such as accounting, finance, information technology, and human resources. Companies can exchange ideas that help each other improve efficiency, and often at a very low cost to either.

- In order to compare more directly to competition without relying solely on publicly available data, companies may enter into benchmarking consortiums in which an outside consultant would collect key data from all participants, anonymize it, and then share the results with all participants. Companies can then gauge how they compare to others in the industry without revealing their own performance to others.

Ongoing leadership

Controlling is a management function, it has to do with maintaining effort towards a goal, focusing on the detail of the work being done. It is worth remembering here that leadership is also ongoing. You cannot set a vision and walk away. As a leader, you need to be constantly reminding people of the worthy goal that you are trying to achieve, and working to build and maintain a healthy culture. Leadership must come before management in the course of achieving any goal, but leadership also works at the same time as management, all of the way through to the completion of the vision.

Key Takeaways

- The control process can be viewed as a five-step process: (1) establish standards, (2) measure performance, (3) compare actual performance with standards and identify any deviations, (4) determine the reason for deviations, and (5) take corrective action if needed.

- Benchmarking is a process for improving overall company efficiency and effectiveness by comparing performance to competitors.

compare their performance on a number of dimensions with the performance of other companies that excel in particular areas